Metal Marvels: Exploring The Future With The Latest In Sheet Metal Machinery Trends

In the ever-evolving landscape of manufacturing and engineering, sheet metal machinery plays a pivotal role in shaping the future of various industries. As technology advances, so does the sophistication and capabilities of these machines, leading to increased efficiency, precision, and versatility. This article aims to delve into the latest trends in sheet metal machinery, exploring how these metal marvels are reshaping the landscape of modern manufacturing.

Industry 4.0 Integration

The fourth industrial revolution, commonly known as Industry 4.0, has brought about a significant paradigm shift in the manufacturing sector. Sheet metal machinery is no exception, with the integration of smart technologies and data analytics becoming increasingly prevalent. Today's machines are equipped with sensors and connectivity features that allow for real-time monitoring, predictive maintenance, and seamless communication between different components of the production line. This integration not only enhances operational efficiency but also enables manufacturers to make data-driven decisions for improved productivity.

Advanced Automation for Increased Efficiency

- Automation has been a game-changer in the sheet metal industry, and recent advancements are taking it to new heights.

- Modern sheet metal machinery is equipped with advanced robotics and artificial intelligence, enabling automated loading and unloading of materials, precise cutting and forming, and even adaptive learning capabilities.

- These advancements not only reduce the need for manual labor but also significantly enhance the speed and accuracy of the manufacturing process.

- The result is a more streamlined and efficient production line, capable of handling complex tasks with minimal human intervention. Gain a deeper understanding of sheet metal machinery trends by exploring further.

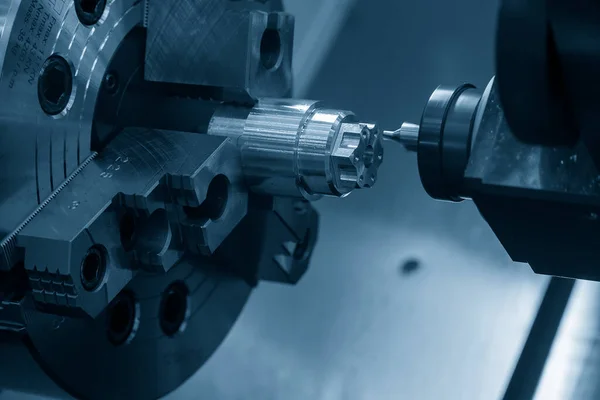

Precision Machining with Laser Cutting Technology

Laser cutting has emerged as a dominant technology in the sheet metal industry, offering unparalleled precision and versatility. The latest trends in laser cutting machinery include the use of fiber lasers, which provide higher cutting speeds and improved energy efficiency compared to traditional CO2 lasers. Additionally, advancements in beam delivery systems and control software have further enhanced the accuracy and flexibility of laser-cutting machines. The ability to cut intricate patterns and complex geometries with minimal waste makes laser cutting an indispensable tool in modern sheet metal fabrication.

3D Printing in Sheet Metal Fabrication

Additive manufacturing, commonly known as 3D printing, has made significant strides in sheet metal fabrication. While traditional subtractive methods involve removing material to create a final product, 3D printing builds up structures layer by layer. This revolutionary approach allows for the production of highly complex and customized components with reduced material waste. The integration of 3D printing in sheet metal fabrication opens up new possibilities for creating intricate designs and prototypes, as well as optimizing the use of materials for improved sustainability.

Hybrid Sheet Metal Machines

- Hybrid sheet metal machines combine multiple manufacturing processes into a single, integrated system.

- These machines can perform tasks such as laser cutting, bending, and even additive manufacturing in a seamless workflow.

- The advantage of hybrid machines lies in their ability to handle a variety of processes without the need for manual intervention or transferring materials between different machines.

- This not only saves time but also increases the overall efficiency of the production line.

Environmental Sustainability in Sheet Metal Manufacturing

As the world becomes more environmentally conscious, the sheet metal industry is also embracing sustainable practices. New trends in sheet metal machinery focus on minimizing waste, reducing energy consumption, and using eco-friendly materials. Some machines incorporate features such as automatic material nesting algorithms to optimize sheet utilization, leading to less material waste. Additionally, advancements in energy-efficient technologies and the use of recycled materials contribute to a more sustainable and environmentally friendly sheet metal manufacturing process.

Augmented Reality (AR) in Sheet Metal Work

Augmented reality is finding applications in various industries, and sheet metal manufacturing is no exception. AR can be used in the training of operators, providing real-time guidance and instructions for complex tasks. It also aids in quality control by overlaying virtual models onto physical products, allowing operators to identify defects or deviations from design specifications. The integration of AR in sheet metal machinery enhances the overall efficiency of the manufacturing process and ensures a higher level of precision in the final products.

Digital Twins for Enhanced Product Development

Digital twins are virtual replicas of physical objects or systems, and they are becoming increasingly popular in the sheet metal industry. In product development, digital twins allow manufacturers to simulate and analyze the behavior of a sheet metal component before it is physically produced. This helps in identifying potential issues, optimizing designs, and reducing the time and cost associated with prototyping. The use of digital twins in conjunction with advanced simulation software is revolutionizing the way sheet metal products are conceptualized and brought to market.

Customization and Small-Batch Production

Consumer demands for customized products and the rise of niche markets have led to a shift in the sheet metal industry towards more flexible manufacturing processes. Modern sheet metal machinery is designed to handle small-batch production runs efficiently, allowing manufacturers to cater to diverse customer requirements. This trend is particularly evident in industries such as automotive and aerospace, where customization of sheet metal components is crucial for meeting specific design and performance criteria.

Global Connectivity and Remote Monitoring

- With the advancement of communication technologies, sheet metal machinery is now capable of global connectivity and remote monitoring.

- Manufacturers can remotely access and monitor their machines, receive real-time production data, and perform diagnostics from anywhere in the world.

- This capability is especially valuable for multinational companies with production facilities in different locations.

- Remote monitoring not only ensures optimal machine performance but also enables quick response to potential issues, minimizing downtime and maximizing productivity.

The future of sheet metal machinery is undoubtedly marked by innovation, automation, and a commitment to sustainability. As manufacturers embrace the latest trends in technology, they are not only enhancing the efficiency and precision of sheet metal fabrication but also contributing to a more sustainable and environmentally friendly manufacturing landscape.

From Industry 4.0 integration to the use of advanced automation, laser cutting, 3D printing, and hybrid machines, the sheet metal industry is evolving at a rapid pace. As these metal marvels continue to shape the future, it's clear that the possibilities for innovation in sheet metal manufacturing are limitless.